Analysis of Physical Testing for Cosmetic Packaging Materials

Barrier Performance Testing

· Oxygen Transmission Rate Testing: Evaluates the oxygen barrier capabilities of packaging films and laminates, protecting ingredients from oxidation.

· Water Vapor Transmission Rate Testing: Ensures that films and containers effectively block water vapor, preventing moisture loss.

· Fragrance Retention Testing: Tests the packaging's ability to retain aromatic gases, preserving the product's fragrance.

Strength Testing

· Tensile Strength, Peel Strength, Heat Seal Strength, Tear Strength, Puncture Resistance: Utilizes electronic tensile testing machines and heat seal testing equipment to ensure the strength and stability of packaging materials.

Thickness Testing

· Measures the uniformity of film or sheet thickness using mechanical contact testing methods to ensure consistent performance.

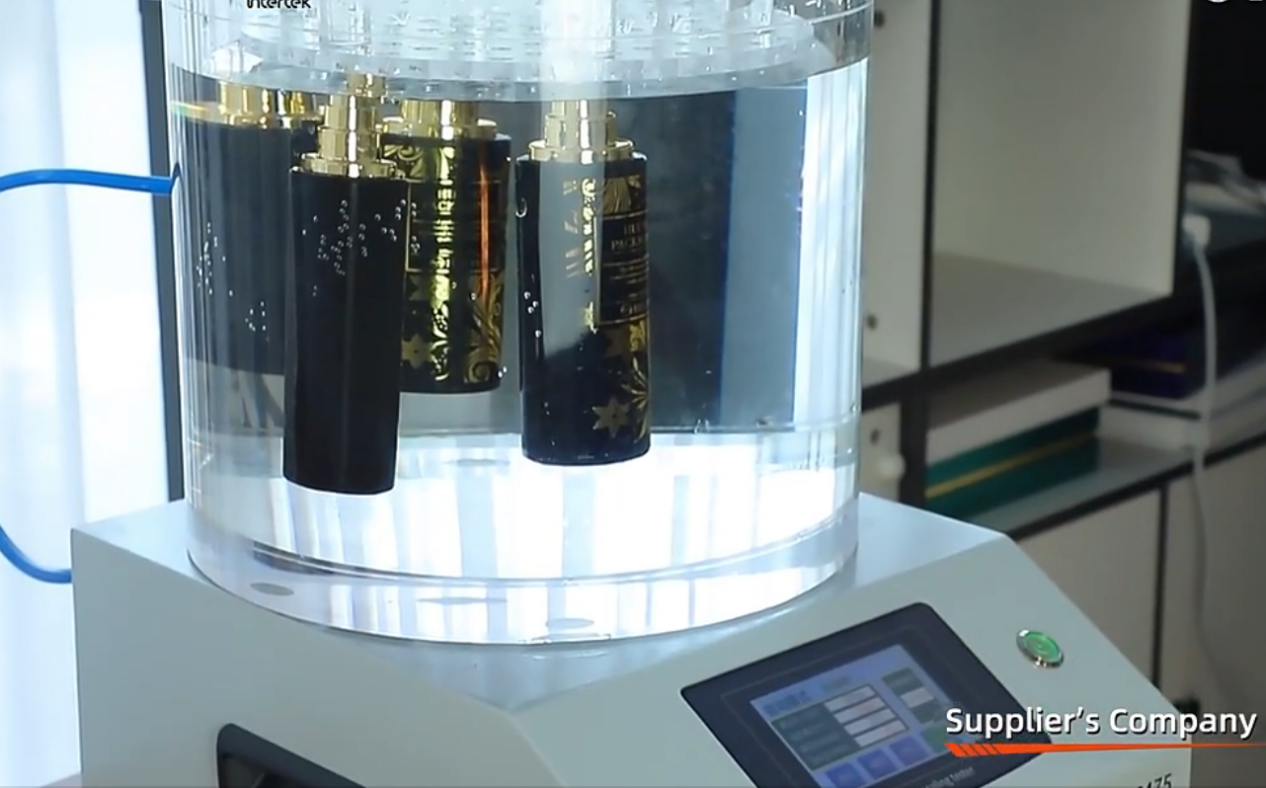

Seal Integrity Testing

· Water Submersion Vacuum Method: Tests the leak resistance of packaging in a vacuum chamber.

· Positive Pressure Testing: Applies pressure to the inside of the packaging to assess its compressive strength and seal integrity.

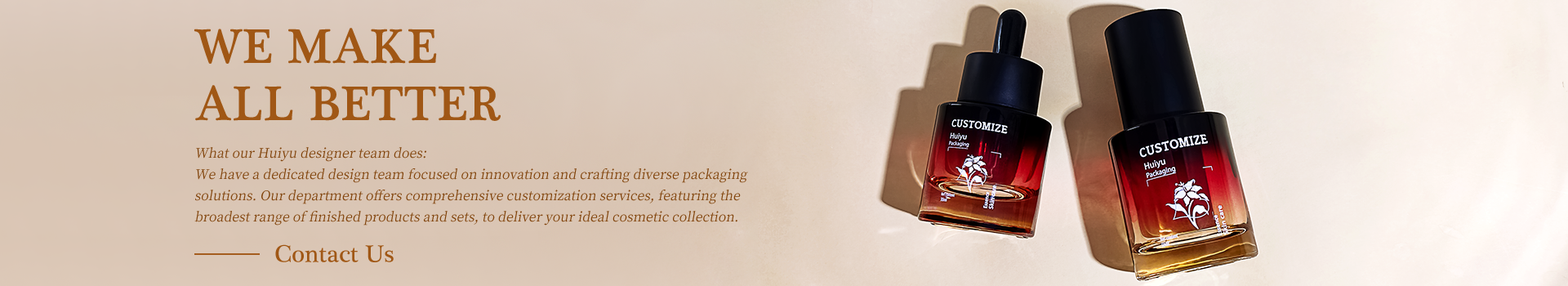

Through these comprehensive tests, Huiyu Packaging ensures that every piece of packaging meets the highest standards, protecting your product quality and the safety of your loyal consumers.

Hot News

-

Explore High-End Perfume Bottle Quality with the Hiuyu Packaging Team

2024-03-22

-

Foreign trade container to avoid five pits, step on the pit to sum up the experience

2024-01-27

-

Unveiling Uniqueness: Huiyu's Extraordinary Perfume Bottle Collection

2024-01-19

-

Where Thank Yous Outshine Even the Shiniest Packaging!

2024-01-05

-

Fresh Arrival HY-1872

2023-12-22

-

How to find samples and suppliers

2023-12-11

-

Silk-Screened On Dropper collar

2023-11-24

-

Casual conversation about the display effects of color on glass bottles

2023-11-13

-

What is the value of recycling of high-grade glass skin care bottles?

2023-10-30

-

Hey, how about customizing the logo and patterns on the cap

2023-10-30

-

Customized Glass Skincare Set: Where Luxury Meets Personalization

2023-10-19

-

How Dropper Bottles Can Attract Consumers Silk printing

2023-10-09

-

Ensuring Pristine Delivery: HUIYU team Commitment to Glass Bottle Shipping and Packaging

2023-09-23

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BE

BE

IS

IS

MK

MK

BN

BN

BS

BS

MN

MN

KK

KK

LB

LB

FY

FY

XH

XH